The “New Normal” for Procurement

Procurement plays an increasingly important role in achieving corporate goals and objectives in the current business landscape. In the utility industry, this means creating value that supports the delivery of safe, reliable, affordable, and clean energy. The focus of procurement has shifted from simply reducing costs to delivering value in other areas such as quality, speed, performance, risk management, and supply assurance. Procurement is also responsible for operational aspects such as organization, efficiency, process, and customer service. At the same time, digital advancements have created new opportunities for procurement in areas such as automation, advanced analytics, systems integration, blockchain, and collaborative tools, which allow for even greater efficiency and effectiveness in an organization.

To control and reduce Operational and Maintenance (O&M) costs, utilities must focus on implementing innovative sourcing and supplier development strategies, measuring their proficiency, and reducing expenses.

Develop O&M Cost Reduction Strategies

Operations & Maintenance (O&M) is focused on a utility’s generation plants, distribution and transmission systems, and general and administrative expenses. These costs are typically represented by both labor and non-labor expenditures associated with running a utility, passed through to ratepayers without a profit markup, and recovered on a dollar-for-dollar basis, rather than gradually over time.

The increases in O&M costs are due to many factors including declining energy sales and revenues, inflation rates rising to the highest level in four decades, global uncertainties, wildfire mitigation, supply chain constraints, customer transparency, and risks associated with the Russia-Ukraine war. Plus, due to the COVID-19 pandemic and raw material shortages, there have been supply chain constraints that have resulted in increased costs for raw materials, finished goods, transportation, and logistics.

Measuring proficiency, and ultimately controlling O&M costs, is paramount to maintaining healthy bottom lines and meeting shareholder expectations. To measure proficiency, many different metrics can be used, such as O&M cost per megawatt-hour (MWh), O&M cost per customer, O&M cost per employee, or O&M cost as a percentage of utility revenue. Utilities can track these metrics to benchmark their performance and develop strategies for improvement. The most important thing is to remain adaptable and responsive in this new landscape. With the right strategies in place, procurement can continue to play a vital role in keeping O&M costs under control and ensuring utilities’ long-term success.

Controlling O&M Costs

To mitigate these increases in O&M costs, utilities must focus on cost control by implementing innovative sourcing and supplier development strategies. Such strategies include:

By taking these steps, utilities can effectively control their O&M costs and keep them from increasing further. This will help maintain healthy bottom lines and meet shareholder expectations. Organizations such as Arroyo Strategy can help develop and implement these innovative sourcing and supplier development strategies to help utilities control their O&M costs.

Implement an O&M Cost Management Program

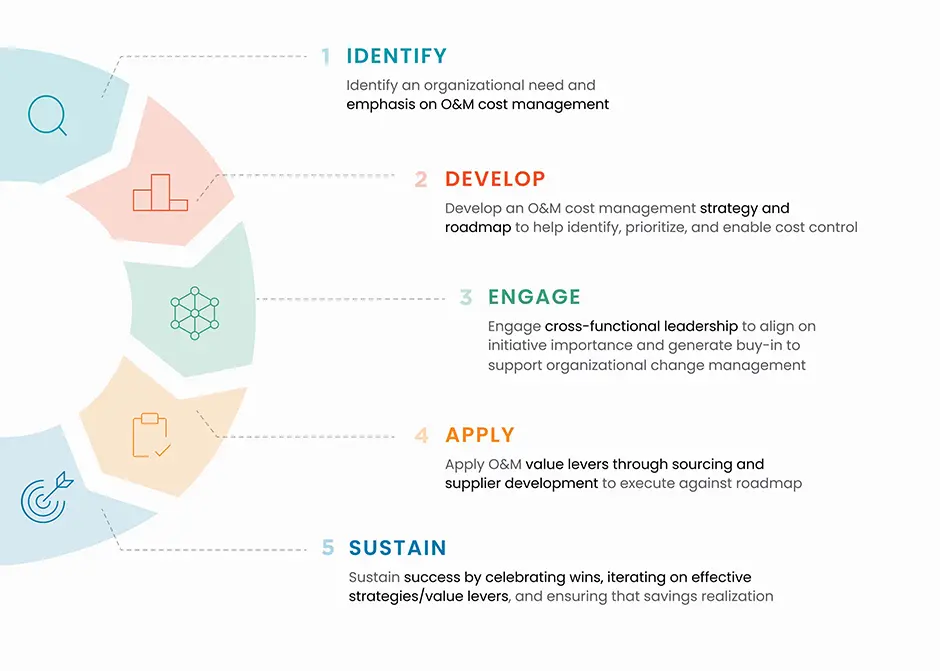

When it comes to controlling and reducing O&M costs, having a well-established program is critical and can help your company stay ahead of the curve. Applying a methodical framework to build, scale, and sustain O&M cost management is the foundation for program success.

To start, your company will need first to measure its proficiency. This can be done by looking at the O&M cost per unit of energy produced (MWh), the number of customers serviced, the revenue generated, or the number of employees. Once you have a benchmark to work from, you can begin to implement changes that will help reduce costs. You can maximize O&M impact by utilizing category management to:

- Increase overall value from the supply base service levels, availability, quality, and the value of money.

- Reduce the total cost of ownership of goods and services.

- Address and mitigate risk in the supply chain.

- Enable supplier capability development and encourage more innovation from the supplier.

- Effectively align and leverage internal resources to deliver to generate through cross-functional teamwork procurement outcomes that fully satisfy agreed business needs.

- Increase value capture through continuous monitoring.

However, these O&M cost reduction strategies need to be sustained to have a lasting and measurable impact. This includes getting full stakeholder involvement to develop a project pipeline and identify business opportunities. It also requires developing strategic relationships with suppliers to maximize value, drive efficiencies, and meet cost-reductions targets.

Case Study: Reducing Full-service Management Consulting Spend

For three years, a California-based utility company noticed a substantial increase in full-service management consulting spend, which highlighted the need for formalized internal governance to validate market rates and project classification. To achieve this goal, the company developed internal governance to:

Maximizing O&M Impact through Category Management

Category management organizes goods and services into categories that accurately represent how the business uses them to improve the overall value from the supply base service levels, availability, quality, and the value of money. Utilizing category management can help reduce the total cost of ownership of goods and services by addressing and mitigating risk in the supply chain, effectually aligning and leveraging internal resources to deliver procurement outcomes that fully satisfy agreed business needs. This can help organizations maximize O&M impact by increasing value capture through continuous monitoring.

By grouping goods and services into categories, businesses can more accurately represent how they use these items. Additionally, by utilizing category management, businesses can encourage supplier innovation and development, leading to even more significant cost savings in the future.